Driving Resilience Decisions Through Better Data

By Kirk Phillips, M.SAME

The Air Force Office of Energy Assurance is demonstrating how a new iteration of resilience assessments can better target and quantify potential vulnerabilities in energy security—bolstering national defense by supporting more informed decisions on resilience improvements at installations.

Every day, our military services see kinetic and cyber-attacks being conducted in global conflicts. These planned and organized counter-energy campaigns serve as stark reminders that resilient energy is foundational to national defense. We must know how resilient our energy systems and supplies are before our adversaries become our enemies.

The Department of the Air Force positions energy as a top priority within its overall defense strategy and strives to continuously refine, improve, and maintain resilient energy infrastructure that is capable of supporting critical missions.

The Air Force Office of Energy Assurance (OEA), operating within the Air Force Civil Engineer Center, is the central organization through which these efforts begin—first with an assessment of installation energy capabilities; and then by the development of relevant, impactful solutions that identify and close energy resilience gaps, with consideration for any potential adversary or environmental act.

Because MRP uses multi-modal inputs, it builds on existing tools that OEA already uses to assess installation energy resilience. These are primarily qualitative in nature, and they enrich data contributions with greater depth and detail.

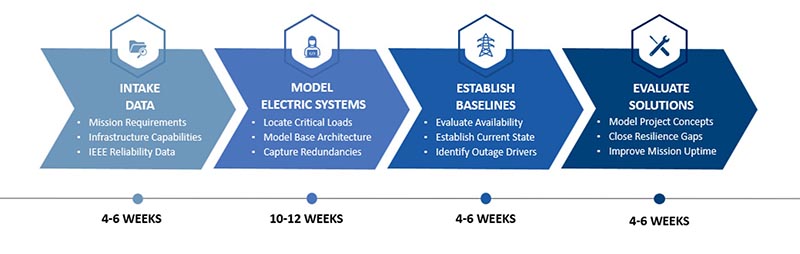

In response to evolving federal law, OEA has accelerated its efforts to improve energy resilience across critical mission facilities. The present strategy begins with refining resilience assessments to yield actionable information. A novel methodology, the Measuring Resilience Process (MRP), is how we highlight and quantify areas of risk to the energy infrastructure of our installations and make more informed decisions about how to prioritize and justify future resilience improvements.

Rigorous Metrics

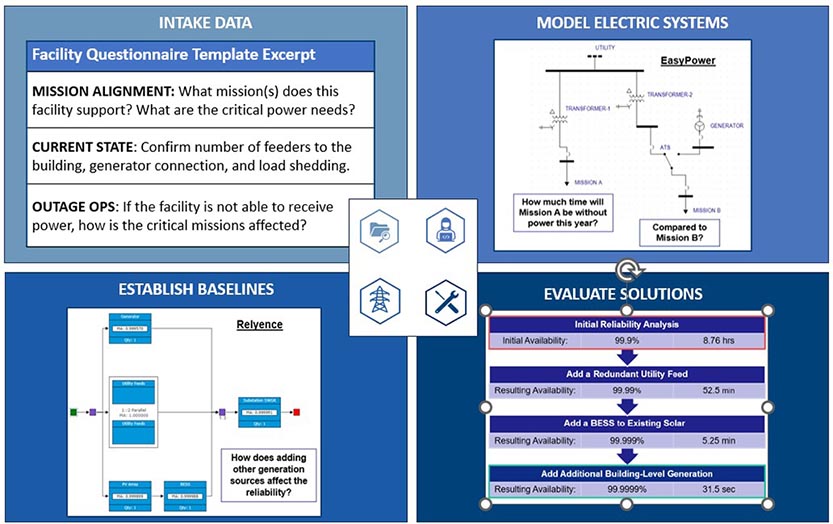

Use of MRP moves the Air Force into alignment with 10 U.S.C. §2920’s energy resilience thresholds for critical mission facilities and the Office of Secretary of Defense’s rigorous metrics and standards for energy resilience at defense installations, instituted in 2021. By 2030, 100 percent of the energy load supporting critical missions must achieve 99.9 percent availability per year. For more critical or sensitive missions, that energy availability requirement ranges from 99.99 percent (allowing only 8.6-hrs of downtime per year) to 99.9999 percent (only 31.5-sec of downtime per year).

The process, developed with a contractor support team from Booz Allen Hamilton, enables installations to understand the energy needs of their critical facilities in terms of the downtime that each mission should expect annually. This metric provides a clear understanding of the impact of energy resilience on mission capability through the risk-to-mission results of outages. Implementing the method can equip leadership with decision-ready information to directly address defense policy and, ultimately, improve mission continuity.

By 2030, 100 percent of the energy load supporting critical missions must achieve 99.9 percent availability per year. For more critical or sensitive missions, that energy availability requirement ranges from 99.99 percent (allowing only 8.6-hrs of downtime per year) to 99.9999 percent (only 31.5-sec of downtime per year).

Coordinating Steps. MRP identifies potential causal factors that could lead to energy outages and provides concept-level redress techniques. The approach begins by coordinating with service leadership and installation personnel in order to identify critical missions occurring at each base. Once those critical missions are identified, they are aligned with the appropriate defense-level requirements; after that, the installation electrical distribution system models are mapped from existing data sources.

Using both a power systems software (EasyPower) and a reliability prediction software (Relyence), MRP quantifies electrical system availability at the point of delivery for critical mission loads. Those results are compared to established standards set by the Office of the Secretary of Defense, and differential analyses are run that incorporate a multitude of combinations of potential solutions in order to assess their relative impacts on critical requirements.

Because MRP uses multi-modal inputs, it builds on existing tools that OEA already uses to assess installation energy resilience. These are primarily qualitative in nature, and they enrich data contributions with greater depth and detail.

Currently, OEA is coordinating joint efforts with the Army Office of Energy Initiatives and Navy Installations Command – Energy to test and scale this process at select military installations. The technical background of MRP makes it relevant across the services. Its methodology is elastic with respect to differing service cultures, perspective on a base’s importance, and the organization of engineer forces. This flexibility also accommodates wide differences of mission requirements, potential threats, and infrastructure characteristics.

The team developing MRP provides overarching support and has established two advisory groups for additional oversight. The Technical Advisory Group continually verifies the quality of MRP and includes representation from the National Renewable Energy Laboratory and MIT Lincoln Laboratory. The End User Advisory Group verifies the applicability of MRP and includes service leads, installation points-of-contact, and members of the development team.

Testing and Reporting. A demonstration effort began in April 2024, with the MRP team speaking with each installation’s energy units to learn more about relevant critical missions and ongoing projects. Each base in the testing program provided one-line diagrams, generator lists, and energy plans. This allowed the team to review and clarify the intricacies of electrical configurations and determine critical mission facilities for analysis.

The technical background of MRP makes it relevant across the services. Its methodology is elastic with respect to differing service cultures, perspective on a base’s importance, and the organization of engineer forces.

In May 2024, the MRP team started utilizing the collected data within EasyPower models. First, this modeling helped define system assumptions for each installation. Second, it helped identify knowledge gaps to resolve during site tours, which got underway in July and occurred throughout the summer. These site visits were an opportunity for the team to brief leadership on the modeling’s indicators, tour electrical systems, and further discuss the demonstration efforts with facility managers. Here, additional data was gathered to refine the model and establish energy baselines. The baseline results provide valuable data for each installation, which will help develop potential solutions and implementation plans.

The demonstration further aims to produce energy resilience insights that are relevant at the service-level and across the defense enterprise, ultimately justifying MRP as a unified and flexible solution.

As the demonstration nears its end in spring 2025, OEA plans to expand MRP to assess additional topics of interest. There are proposals to use the method to study energy resilience in the contexts of extreme weather, adversary action, and equipment degradation due to age. There is also interest in applying the method to areas other than power, such as mechanical, fuel, and water systems.

Addressing Risks

As a method that is more robust than its predecessors, MRP serves as an analytical boon to energy resilience assessments. Granular, quantitative data creates a close-range, detailed assessment of an installation’s unique energy resilience needs.

MRP’s sharper focus allows installations to meet and report energy resilience thresholds in a way that more directly speaks to policy expectations while clearly communicating risk to mission.

The data developed informs and substantiates both immediate and long-term decisions about how installations prioritize investments that reinforce their energy infrastructure against potential disruption of warfighter capabilities or enterprise-wide operations.

Tracking Vulnerabilities

By linking measured energy vulnerabilities to missions in terms of risk, MRP functions as a sturdy framework to understand, change, and track vulnerabilities and their operational impact. This information allows installations to be proactive in addressing energy gaps before they are triggered naturally or exploited by outside forces.

In aiming to increase energy resilience today, MRP is a promising tool that is well-suited to advance ongoing efforts, while remaining agile enough to future demands. It offers four directly measurable impacts: leverages quantitative methods to assess downtime; compliance with codes and requirements; encourages standardization; and helps to analyze and prioritize projects.

MRP is an actionable, asymmetric solution to protect against potential adversaries and enhance national defense.

Kirk Phillips, M.SAME, is Director, Air Force Office of Energy Assurance; kirk.phillips.3@us.af.mil.

Published in the March-April 2025 issue of The Military Engineer

Check Out Related Articles From TME

-

Deploying Renewable Generation Through Small-Scale Hydropower

A field demonstration and ongoing investigation of modular hydrokinetic turbines by the U.S. Army Engineer Research & Development Center’s Construction Engineering Research Laboratory illustrates the potential applicability for using the technology on military deployments. -

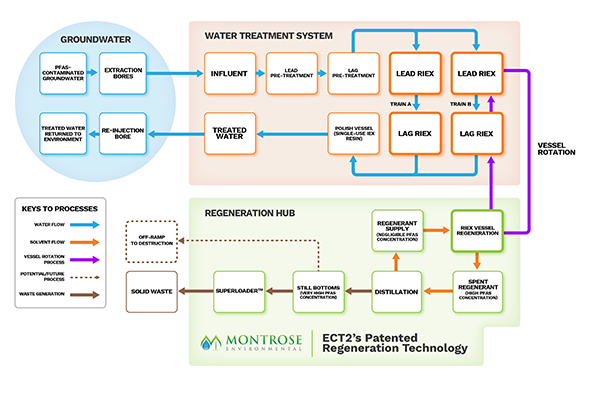

Rethinking Traditional Treatment Systems for PFAS Remediation

At two U.S. Air Force bases impacted by historical releases of aqueous film-forming foam, innovative methods in treating PFAS in both surface water and groundwater provide examples of success in safeguarding health for military personnel and nearby communities. -

Tackling Restoration Projects With Amphibious Excavators

When faced with soft and wet underfoot conditions, such as at a recent channel dewatering, excavation, and repair project for USACE Galveston District, amphibious excavators offer a scalable way to contour difficult site characteristics. -

Big Job, Small Solutions: Completing a Complex Remediation in Remote Alaska

At a remote federal remediation site in south-central Alaska, inaccessible by road, barge, or large planes, leveraging the local community and a fleet of snowmobiles and small watercraft allowed for 1,100 bags of contaminated soil to be transported for offsite disposal. -

Regenesis Offers Full-Spectrum PFAS Remediation

For project stakeholders and remediation managers confronted with PFAS, Regenesis demonstrates why in situ treatment using Regenesis’ PlumeStop® colloidal activated carbon (CAC) is a game changer. -

100 Percent PFAS Compliance with Regenerable Ion Exchange Resin

The operational success of a RIEX system spotlights its successful approach to combating PFAS in an effective and economical manner. (Sponsored Content)