Electrifying Solutions for Military Installations

By Brodie Heflin, P.E., M.SAME, and Wesley Edwards, P.E., M.SAME

As military installations implement electrification measures into the future, the challenges they face will not just require innovative technology solutions but embracing a holistic delivery approach implemented early in projects.

Electrification describes the transition from the end use of fossil fuels to power systems and infrastructure to electricity. Across military facilities, the implementation of electrification is primarily concentrated on HVAC, culinary, and heating sources. Broadly, it supports a need to reduce Scope 1 greenhouse gas emissions (those occurring from sources directly owned or controlled by an organization) in order to meet sustainability goals and achieve net-zero targets.

Although there is currently no active policy in place requiring military facilities to transition away from fossil fuels, public opinion and cultural shifts are demanding that utilities consider alternative sources for energy beyond traditional fossil fuel burning. Energy security is also strengthened by incorporating additional sources of onsite-available energy generation.

Meeting these trends over the long term will not only require innovative technology solutions but embracing an integrated approach to delivery to make the transition as seamless as possible.

Technology Approaches

When considering all-electric technology solutions for the built environment, there are two options to evaluate.

The first approach focuses on electric resistance heating elements. These comprise air heating coils (such as unit heaters, duct heaters, and air handler electric coil sections) and water heating appliances, which include electric boilers and water heaters. The main challenge with electric resistance heating is that it is only 100 percent efficient. This may sound counterintuitive, but competitive all-electric technology needs to be more than 100 percent efficient because natural gas is considerably cheaper than electricity. The second option is heat pumps. This technology operates on the refrigeration cycle, like cooling systems. It can produce heat with an efficiency greater than 100 percent. Heat pumps are separated into three categories, distinguished by where they extract heat.

Air-source heat pumps. Air-source heat pumps extract heat directly from the air. They operate using the refrigeration cycle. Typically, they are rated using their coefficient of performance (COP). The COP allows the heat pumps to produce a larger unit of heat than the electricity that is used to power them. For instance, if the heat pump has a COP equal to 3, it means that for every 1 unit of electrical energy used, the pump produces 3 units of heat. Climate conditions are less of a diminishing factor, but still a consideration in frigid settings. At outdoor temperatures above 0°-F, air-source heat pumps typically operate with a COP greater than 2; this makes them highly efficient in cold to moderately cold climates. The main drawback with air-source heat pumps is that in very low outdoor temperatures, the amount of heat that can be extracted is much lower and efficiency drops dramatically. In extremely low outdoor air temperatures, air-source heat pumps need to turn off to prevent damage to the equipment. Either electric resistance heating or fossil fuels are needed to completely heat the building.

Water-source heat pumps. Water-source heat pumps operate in a similar manner to air-source heat pumps, but extract heat from a condenser water loop. They face the same limitations, though, if the condenser water loop is connected to an air-cooled source such as a cooling tower or a closed loop cooler.

The main challenge with electric resistance heating is that it is only 100 percent efficient. This may sound counterintuitive, but competitive all-electric technology needs to be more than 100 percent efficient because natural gas is considerably cheaper than electricity.

Ground-source heat pumps. Ground-source heat pumps extract heat from the earth. As a near constant temperature source, the ground provides an ideal place to extract heat. The fact that the heat rejection is independent of the climate conditions means that ground source heat pumps can be operated at virtually any outdoor air temperature and provide adequate heating for buildings. However, this solution requires the installation of deep wells for the ground loop and a balanced thermal profile for the building, which shows that heating and cooling are balanced. The initial cost of these systems is high; and redundant heating or cooling equipment is required to balance the thermal profile if the building is primarily in heating or cooling mode.

While these technologies each are effective in implementing electrification, solution providers need to consider supportive strategies that ensure they are also efficient from a cost perspective. For example, electric resistance heat systems will drive an increase in electric utility. Air source heat pumps pose operational challenges as they shut down on low temperatures and require electric resistance heating for backup. By default, both solutions raise costs.

Integrated Delivery

When implementing electrification measures at military facilities, it is vital to deploy a holistic, integrated approach right from the early stages. This is especially important in the built environment, where any change or modification in a requirement typically impacts multiple stakeholders in adjacent areas.

Electrification brings changes in heating systems. It will impact the electrical grid. Implementation has the potential to affect project management, operations and maintenance, planning, utilities, and design. An integrated approach will ensure that these potential changes, and any resulting disruptions, are minimized. This will also support a reduction in electrical demand across the facility, ensuring that costs are reduced.

At the outset of a military electrification project, design teams should review existing infrastructure, establish standards, and determine appropriate actions. They also need to evaluate limitations and capabilities of the existing infrastructure, with a focus on site electrical distribution and building service.

Setting Baselines

Project teams should evaluate existing building electrical demand, provide energy audits, and evaluate thermal trend data. This information will establish electrical demand and energy consumption design targets that receive buy-in from all stakeholders.

Once projects are approved, teams, working collaboratively, will deliver integrated solutions to meet these targets: these include architectural design based on the local climate to reduce energy use in new buildings and retrofits; thermal storage; the use of geo-exchange systems; and the integration of heating systems into building structures and facades.

To further drive down electrical demand, the project scope should include efforts that reduce heating requirements through capturing waste heat, changes to operations, and pre-heating outdoor air. Capturing waste heat should be focused on energy recovery devices, waste heat capture from condensers and high heat equipment such as computers, and waste heat recovery from sanitary systems. Operational changes can include turning off equipment and the implementation of off-hours usage policies. Similarly, implementing automatic shutoff for lighting and equipment removes the need to rely on individuals to flip switches. To pre-heat outdoor air, best practice includes the use of façades like solar walls, which can be readily installed on commonly available base facilities such as hangars and warehouses.

Making the Switch

While military organizations are already committed to energy resiliency and energy reduction in order to enhance overall readiness and security, project requirements sometimes accelerate the timeline for facilities, systems, and buildings to implement electrification measures and phase out fossil fuel usage.

Best practice in this regard centers on an integrated approach to project delivery—ensuring that impacts are minimized and stakeholders unaffected. A focus on implementing innovative all-electric technology solutions, supported by cost-effective strategies, will ensure that site owners make a seamless switch to electrification, moving to embrace the mission-enhancing benefits while limiting any inherent trade-offs.

Running the Numbers

Fossil fuels comprise 82 percent of the country’s source energy usage, with the balance made up from nuclear and renewables. In addition, approximately 65 percent of source energy is directly delivered for end use, with the remainder used to generate and distribute electrical power.

Buildings are responsible for 40 percent of total energy use in the United States and for 35 percent of carbon emissions. The Defense Department is the largest single user of facility energy in the country. Electrification measures at military installations into the future represent a considerable opportunity to reduce overall emissions and enhance energy security while supporting broader decarbonization goals.

Electrification has the potential to insulate agencies from the uncertainty of fossil fuel prices. The reduction of fossil fuel-burning equipment also lowers the risk of fires and carbon monoxide leaks and provides cleaner indoor air for staff.

However, the other, broader impact of electrification is cost—and so the benefits must outweigh the cost enough to warrant adoption, or, accept that higher costs sometimes are acceptable to increase energy independence and redundancy. On average, electric energy unit costs in the United States are four times those of natural gas unit costs. Typically, in the built environment, fuel or gas-fired equipment comprises heating equipment as well as generators, fire pumps and process equipment. Changing the heating equipment to electric resistance can significantly impact electrical service and utility costs. For example, installing electric resistance systems in a mission-critical building will require a transformer and generator that are considerably larger than the equipment required for natural gas systems. And with an increase in electricity demand, the facility’s energy costs will increase.

Brodie Heflin, P.E., M.SAME, is Mechanical Engineering Manager, and Wesley Edwards, P.E., M.SAME, is Mechanical Engineering Group Lead, Jacobs. They can be reached at brodie.heflin@jacobs.com; and wes.edwards@jacobs.com.

Published in the March-April 2025 issue of The Military Engineer

Check Out Related Articles From TME

-

Deploying Renewable Generation Through Small-Scale Hydropower

A field demonstration and ongoing investigation of modular hydrokinetic turbines by the U.S. Army Engineer Research & Development Center’s Construction Engineering Research Laboratory illustrates the potential applicability for using the technology on military deployments. -

Rethinking Traditional Treatment Systems for PFAS Remediation

At two U.S. Air Force bases impacted by historical releases of aqueous film-forming foam, innovative methods in treating PFAS in both surface water and groundwater provide examples of success in safeguarding health for military personnel and nearby communities. -

Tackling Restoration Projects With Amphibious Excavators

When faced with soft and wet underfoot conditions, such as at a recent channel dewatering, excavation, and repair project for USACE Galveston District, amphibious excavators offer a scalable way to contour difficult site characteristics. -

Big Job, Small Solutions: Completing a Complex Remediation in Remote Alaska

At a remote federal remediation site in south-central Alaska, inaccessible by road, barge, or large planes, leveraging the local community and a fleet of snowmobiles and small watercraft allowed for 1,100 bags of contaminated soil to be transported for offsite disposal. -

Regenesis Offers Full-Spectrum PFAS Remediation

For project stakeholders and remediation managers confronted with PFAS, Regenesis demonstrates why in situ treatment using Regenesis’ PlumeStop® colloidal activated carbon (CAC) is a game changer. -

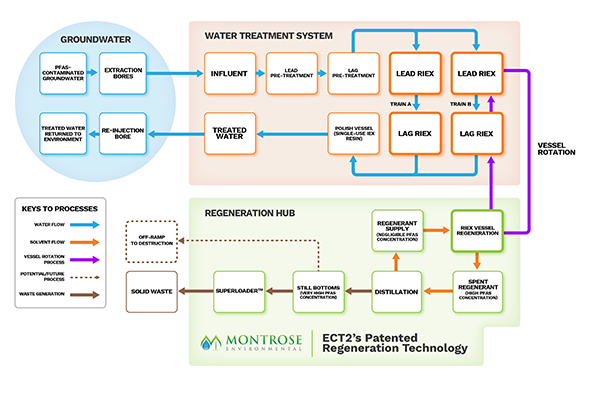

100 Percent PFAS Compliance with Regenerable Ion Exchange Resin

The operational success of a RIEX system spotlights its successful approach to combating PFAS in an effective and economical manner. (Sponsored Content)