Leading the Way: Partnering for Resiliency and Readiness

TME Interview with Brig. Gen. Patrick Miller, P.E., F.SAME, USAF Commander, Air Force Civil Engineer Center

TME Leader Profile

TME: Can you describe AFCEC’s mission, goals, and objectives?

MILLER: The Air Force Civil Engineer Center (AFCEC), by providing civil engineering expertise and support for the full spectrum of air and space operations, plays a critical role in serving the Department of the Air Force. As a subordinate command to the Air Force Installation & Mission Support Center (AFIMSC), AFCEC is a crucial component in the daily operation of ensuring the readiness and sustainability of U.S. Air Force and U.S. Space Force installations worldwide.

Our mission is to deliver civil engineering expertise, strengthen installations, and enhance combat power. This includes a wide range of civil engineering functions—from facility sustainment and infrastructure maintenance to disaster response and energy management. We focus on improving installation readiness, optimizing infrastructure, and enhancing energy security, all of which contribute to operational readiness and resilience.

Our mission is to deliver civil engineering expertise, strengthen installations, and enhance combat power.

We do not accomplish our work in isolation. To deliver timely, organized, and scalable mission support that is focused on rapid recovery and operational continuity, AFCEC collaborates at more than 75 locations worldwide with the other organizations that comprise AFIMSC, as well as installation and mission support teams across the Department of the Air Force, industry partners, and other federal agencies.

This commitment to working together enables our ability to expeditiously implement civil engineering policies and deliver capabilities to the field in this era of Great Power Competition.

TME: How have your previous positions influenced your approach to this leadership role?

MILLER: Winston Churchill once said: “To each there comes in their lifetime a special moment when they are figuratively tapped on the shoulder and offered the chance to do a very special thing, unique to them and fitted to their talents. What a tragedy if that moment finds them unprepared or unqualified for that which could have been their finest hour.”

What I have found in the military is that no career path is the same. I am different from every other AFCEC commander, and that is a good thing. Anyone interested in perusing my background will see that I have garnered experience in the Pentagon, at Major Commands, across multiple deployments, through Squadron, Group, and Wing command positions, and as an instructor at The Civil Engineer School. I also served as the Deputy for AFIMSC, our parent command, and responded to a number of natural disasters and mishaps.

Each evolution was a learning experience, an opportunity to grow. That is the key. No matter your path, every interaction and touch point is a chance to listen, learn, and improve. I would not say any single position during my career influenced my approach to this role. All of them did. I value each relationship, experience, and lesson experienced.

TME: How is AFCEC helping answer the engineering-related requirements resulting from near-peer competition?

MILLER: Near-peer competitors, primarily China, pose significant challenges to the national defense. AFCEC is working to help the Department of the Air Force stay ahead of threats by training, equipping, and preparing for contingencies on an ongoing basis. Our mission covers all aspects of enhancing installation effectiveness, sustainability, and readiness. Through collaboration, we can ensure that we effectively meet the needs of a larger community to prepare and present a united front.

To address the challenges from near-peer competition, we are accelerating procurement, resourcing, and sustainment capabilities to support contingency operations. We must be ready to respond to a full-blown conflict on multiple fronts, terrorist attacks, and cyberattacks. We must maintain our capability to respond to natural disasters like hurricanes, earthquakes, and floods and keep our power-projection platforms mission-ready.

In these circumstances, AFCEC’s primary responsibilities are providing reach-back subject matter expertise, deploying civil engineering professionals and equipment, and executing projects supporting surge operations. AFCEC also deploys capability-enhancement teams such as civil engineer maintenance, inspection, and repair teams; airfield pavement evaluation teams; and natural disaster response and recovery units. This support covers all aspects of enhancing installation effectiveness and readiness.

TME: What are some opportunities and challenges you see for the civil engineering community, today and moving forward?

MILLER: The Department of the Air Force has an immediate need to modernize aging infrastructure. We need to design and build resilient and adaptable infrastructure to combat evolving threats and dynamic operating environments. The Air Force has set goals to reduce energy consumption and increase usage of renewable energy. The civil engineering community must comply with environmental and safety regulations as well. These can be time-consuming and costly; however, the challenges do present significant opportunities for growth and development.

In addition to prioritizing resiliency, the Air Force can harness the power of emerging technologies to drive innovation. For example, we must leverage advances in materials science and technology to create new infrastructure solutions that are stronger, more durable, more sustainable, and cost-competitive.

We have already fielded and are exploring the further potential of autonomous systems. Deploying drones and robots may enhance civil engineering tasks like inspections and maintenance. As the use of AI becomes trusted and more standardized across our discipline, we will use it. At the same time, we will continue to collaborate with domestic and international partners to share best practices, develop common standards, and foster a more cohesive approach to ensure that the Air Force remains mission-ready, secure, and capable of facing present and future challenges.

TME: As a Fellow in SAME, what value have you seen from your involvement with the Society?

MILLER: I have had the privilege to serve the Society in a variety of volunteer roles: Post President, Chair of the Young Member Council, elected member of the Board of Direction. SAME exposed me early on to the power of relationships and collaboration. The Society is filled with extraordinary leaders poised to attack our nation’s most wicked challenges. True success is realized when the public and private sectors synergize. Because of SAME, I have a rolodex of colleagues eager to share mentorship and advice.

Equally important, the Society capitalizes on the collective expertise of the engineering community to help resolve issues like setting the Pacific theater to protecting infrastructure across the home front. And the various Communities of Interest amply our combined focus. Lastly, the Society invests in the future, mentoring and developing current and future leaders of our profession, from the STEM/Engineering & Construction Camps to Post meetings and workshops to the Leader Development Program, to opportunities for service components to train together. I truly appreciate the Society’s efforts to make us better every day. I challenge our members to not only take advantage of what SAME offers, but to jump in and make it better!

TME: How is AFCEC engaging with industry and other government agencies to deliver its programs and advance innovation?

MILLER: Our relationship with the private sector and other agencies is instrumental. Engaging with industry has resulted in many initiatives and programs that not only protect installations, improve readiness and resilience, and enhance critical infrastructure, hey contribute to quality of life for our airmen, Guardians, and their families who work, live, and learn on our bases.

AFCEC’s alliances are not just about collaboration, but also innovation. These partnerships have led to the development of new construction technologies with the U.S. Army Corps of Engineers, energy-efficient technologies with federal partners, cybersecurity solutions with private industry, and construction and infrastructure management tools with academia.

We are currently working with a company that developed a cybersecurity architecture that leverages commercial best practices and automation to enhance cybersecurity across systems. Another firm we are working with has developed a virtual reality simulator that provides an immersive, high-fidelity training environment for the management of airbase recovery activities. This symbiotic relationship enables AFCEC to harness the latest technologies and innovations, which enhances the delivery of programs and advances our overall mission.

TME: How can organizations like SAME support AFCEC?

MILLER: AFCEC relies on a strong network of like-minded organizations to effectively conduct operations. I view SAME as an important partner in that network for sharing knowledge, facilitating collaboration, and fostering partnerships between industry, academia, and government.

From local Post meetings to the Federal Small Business Conference and Joint Engineer Training Conference at the national level, SAME provides platforms to build relationships and connect requirements with solutions.

Brig. Gen. Patrick Miller, P.E., F.SAME, USAF, became Commander, Air Force Civil Engineer Center, in July 2024. Previously, he was Director of Logistics, Engineering & Force Protection, HQ Pacific Air Forces. Other command assignments include Commander, 88th Air Base Wing; Vice Commander, Air Force Installation & Mission Support Center; Commander, 6th Mission Support Group; and Commander, 628th Civil Engineer Squadron. Miller entered the U.S. Air Force in December 1997 as a distinguished ROTC graduate at Pennsylvania State University. He was named NSPE Federal Engineer of the Year in 2015.

Published in the March-April 2025 issue of The Military Engineer

Check Out Related Articles From TME

-

Deploying Renewable Generation Through Small-Scale Hydropower

A field demonstration and ongoing investigation of modular hydrokinetic turbines by the U.S. Army Engineer Research & Development Center’s Construction Engineering Research Laboratory illustrates the potential applicability for using the technology on military deployments. -

Rethinking Traditional Treatment Systems for PFAS Remediation

At two U.S. Air Force bases impacted by historical releases of aqueous film-forming foam, innovative methods in treating PFAS in both surface water and groundwater provide examples of success in safeguarding health for military personnel and nearby communities. -

Tackling Restoration Projects With Amphibious Excavators

When faced with soft and wet underfoot conditions, such as at a recent channel dewatering, excavation, and repair project for USACE Galveston District, amphibious excavators offer a scalable way to contour difficult site characteristics. -

Big Job, Small Solutions: Completing a Complex Remediation in Remote Alaska

At a remote federal remediation site in south-central Alaska, inaccessible by road, barge, or large planes, leveraging the local community and a fleet of snowmobiles and small watercraft allowed for 1,100 bags of contaminated soil to be transported for offsite disposal. -

Regenesis Offers Full-Spectrum PFAS Remediation

For project stakeholders and remediation managers confronted with PFAS, Regenesis demonstrates why in situ treatment using Regenesis’ PlumeStop® colloidal activated carbon (CAC) is a game changer. -

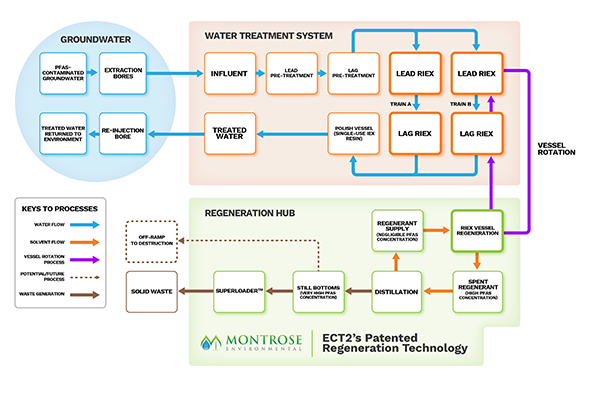

100 Percent PFAS Compliance with Regenerable Ion Exchange Resin

The operational success of a RIEX system spotlights its successful approach to combating PFAS in an effective and economical manner. (Sponsored Content)