By Gretchen Tabano, P.E., M.SAME, Caitlyn Martin, P.E., M.SAME, Brian Grassmyer, M.SAME, and Ryan Steigerwalt, M.SAME

Located in the northwest corner of South Carolina, Camp Croft served as one of the U.S. Army’s principal infantry replacement training centers during World War II. Through its five years of operation between 1941 and 1946, the installation prepared more than 250,000 soldiers for combat. Its training specialization focused on the use of small arms, antitank armaments, anti-aircraft armaments, mortars, and artillery. Today, Camp Croft is a high priority Formerly Used Defense Site, encompassing 19,044-acres of the historical cantonment area and military munitions training ranges.

Situated within the site boundary is Croft State Park, a popular regional recreational destination that receives 170,000 visitors a year. Past military munitions use has created an unacceptable explosive safety risk to park workers and users. To address the possibility of exposure, a remedial action is being conducted through a multi-year Military Munitions Response Program led by both Savannah District and Wilmington District of the U.S. Army Corps of Engineers (USACE), the U.S. Army Engineering & Support Center, Huntsville, and Weston Solutions. The effort is addressing munitions and explosives of concern within the Project 07 Munitions Response Site, which encompasses more than 1,277-acres of Croft State Park.

To achieve the remedial action objective, geophysical detection and positioning technologies are being used at an unprecedented scale and under challenging site conditions. Deliberative technology selection, enhancements, and deployment are necessary to balance the needs and expectations of the state park land manager alongside an emphasis to use advanced geophysical classification (AGC) at Formerly Used Defense Sites to the extent possible.

UNIQUE SITE CONDITIONS

The rolling, densely forested terrain at Croft State Park is a natural resource coveted by the local community and a popular destination for outdoor enthusiasts. Regulations stipulate that both mature and other specific tree species cannot be cut down. A number of former homesteads, cemeteries, and other culturally significant sites adorn the landscape and are required to be protected.

Previously, analog geophysical methods would be the preferential approach for munitions remediation at this type of site. Analog technology is more efficient over difficult terrain and helps maintain a natural landscape by limiting the amount of vegetation removal required. However, utilizing analog geophysics would not achieve the established remedial action objective for the Camp Croft project.

Evaluating object characteristics. AGC technologies allow analysts to decide whether a buried metal object has the characteristics of military munitions and requires excavation, or if it is metallic debris that can be left in place. AGC can significantly reduce investigation efforts by focusing resources on detecting and excavating only items that have potential explosive safety concerns.

Geophysical sensor operators collect full coverage mapping data to locate buried metallic objects, often implementing a two-phase approach. That is followed by static measurements at each detection location to provide geophysical data necessary to make classification decisions. Due to the size and remoteness of Croft State Park, and the contracted performance schedule, project execution required creative use of new and emerging AGC technologies to reduce impacts to public recreation and achieve the contract schedule.

Site usage and natural balance will always be contributing factors to remedial design at Formerly Used Defense Sites that involve significant public access and recreational use. However, effectively executing the remedy to meet the remedial action is exponentially more complicated with the increased importance of collecting robust, high-quality, and defensible AGC data.

CAREFUL DEPLOYMENT

For Croft State Park, White River Technologies’s APEX system was selected for use. APEX is an AGC sensor that collects the data necessary to make classification decisions in one pass and eliminates the need for static measurements at each buried item location. A total of six APEX systems, the first large-scale deployment of its kind, have been in operation at Croft State Park since February 2021.

APEX’s deployment across the site’s complex environmental conditions entails extraordinary startup and preparation activities. Working within protected, closely spaced mature growth trees requires careful manual and mechanical vegetation reduction. Proof-of-concept demonstrations of the process were witnessed and approved by park officials prior to full-scale implementation.

All work is designed to maintain the health of the forest and natural landscape during and after remediation. Undergrowth is surgically removed to the ground surface to provide safe access for the APEX units. A network of geodetic survey control points spaced at 100-ft increments is necessary due to tree density and topography. Conventional ground survey stake-out methods were required due to tree canopy and topographic terrain that prohibited the use of GPS. Nearly 3,100 control points established by surveyors ensure that geophysical data is accurately positioned and repeatable to centimeter-level accuracy. The control network also was originally used by field teams for navigation and positioning with robotic total station (RTS), which provides automated optical electronic distance measurements through line-of-sight.

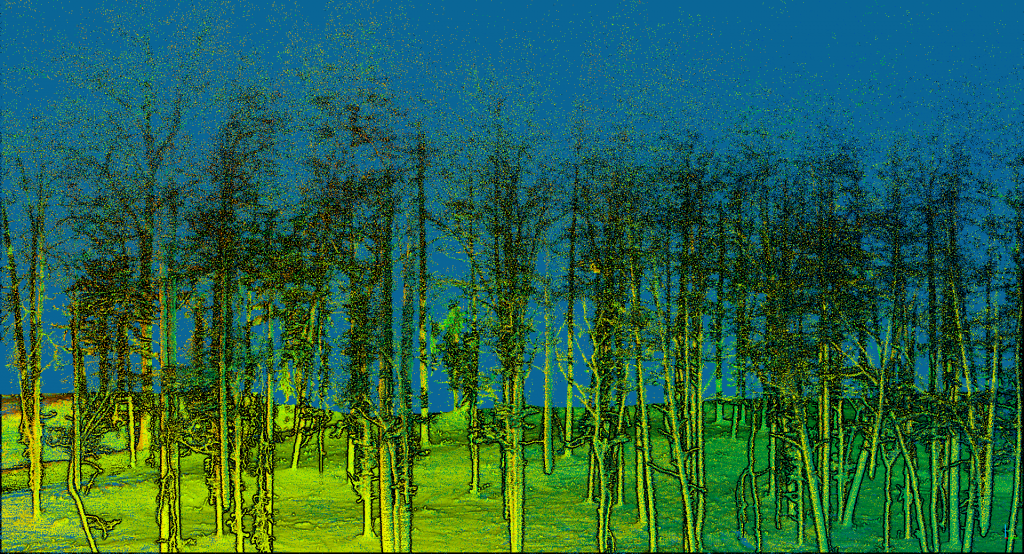

Positioned for results. Because extensive tree removal was prohibited, the density of the remaining trees minimized the efficacy of RTS positioning due to line-of-sight restrictions. When integrated with APEX, instruments utilizing RTS positioning greatly impaired geophysical survey production rates and limited coverage around trees and topographical obstacles where optical tracking was impossible. To increase overall performance, a series of site-specific integration tests were performed with a new technology—simultaneous localization and mapping (SLAM)—that was developed by KAARTA and originally piloted by USACE’s Environmental & Munitions Center of Expertise. KAARTA’s Stencil uses the SLAM process for positioning. A high-precision 3D laser point cloud can be rapidly collected, which allows the device to determine location without the need for line-of-sight or satellite connectivity. SLAM technology, combined with APEX, helps field teams collect AGC data around trees while maintaining a constant positional data stream, resulting in an immediate boost in production rates. Over the last two years, the project at Camp Croft has completely transitioned from RTS to SLAM for all APEX units, increasing survey production by 200 percent.

SPEED, AND QUALITY

Progressive and adaptable approaches to innovative technology integration have been key to providing an efficient remediation solution with minimal impacts to visitors. The willingness of the project delivery team to consider and ultimately accept the use of the latest AGC and positional technologies has enhanced the overall quality and performance across the park.

Remediation efforts are approximately 60 percent complete, with fieldwork anticipated to be done in June 2024. More than 87,900 buried metal detections have been encountered; and by using AGC, a total of 11,500 locations have been determined to require excavation. This 88 percent reduction in excavations significantly reduces overall project schedule, but, more importantly, limits impacts to the park resources and surrounding environment. To date, 5,300-lb of munitions debris and 11 munitions and explosives of concern have been safely located and removed. This includes three MK II Hand Grenades; one M49 Trip Flare; four 60-mm M49 HE mortars; two M17A1 Rifle Grenades – Flare; and one M1 fuze.

MODELING THE APPROACH

The work completed at Camp Croft showcases how the integration of new technologies can provide more efficient, high-quality results that meet the objectives of both local stakeholders and the Department of Defense—facilitating the collective goal of ensuring a safer recreational area for generations to come.

This approach is being evaluated to model its use at other closed military ranges and is expected to aid in data collection efficiencies.

More News from TME

-

A Standardized Approach to Aircraft Fire Training Infrastructure

To support enterprise-wide airmen readiness, the U.S. Air Force is modernizing its standard design for aircraft fire training facilities—introducing digital controls, dual-fuel systems, and PFAS-conscious infrastructure. -

Delivering Energetic Materials Manufacturing Facilities

Designing and constructing facilities that manufacture, process, handle, or store explosives and energetic materials present some of the most challenging defense projects—requiring technical experience, strict safety protocols, and a comprehensive understanding of regulatory frameworks. -

Forging Tradition and Innovation: A New Design Standard at Camp Lejeune

The II MEF Headquarters at Camp Lejeune blends Georgian Revival architecture with modern sustainability—delivering durability, efficiency, and precision that meets contemporary functional requirements while honoring heritage.