Relationships, Resiliency, and Readiness: Increasing Interoperability Through Combined Joint Engineering Operations

By Cdr. Edward Fosson, P.E., M.SAME, CEC, USN

The annual base defense exercise at Marine Corps Air Station Iwakuni brought together engineering forces across the Indo-Pacific, along with members of the Japanese Ground Self-Defense Forces, to gain bilateral training, forge relationships, and increase interoperability in a joint environment.

In October 2024, in the southwestern corner of Japan, off Aki Gulf, Marine Corps Air Station Iwakuni combined its annual base defense exercise with a bilateral exercise of the Japanese Self-Defense Forces in order to test defense, protection, and recovery-after-attack capabilities. Situated between the Chugoku Mountains and the Seto Inland Sea, the installation hosted multiple Japanese Ground Self-Defense Force units from throughout the region for KEEN SWORD 2025. The training included a contingency engineering mission that was built on lessons learned in airfield damage repair gathered during exercises in previous years.

Engineering forces from across the region converged last fall on Air Station Iwakuni for 10 days of drills and instruction to forge relationships, resiliency, and readiness. The observations and insights gathered will influence investments in training, equipment, supplies, and organization at each participating unit.

This latest iteration of KEEN SWORD was unique because the shore-based installation command led contingency operations as part of the regional base defense cluster coordinator.

Meeting Objectives

Preparation for the exercise began months in advance. Steps included a mission analysis to identify specific training objectives and drills desired by each operational unit. Balancing finite resources like time, manpower, materials, and equipment against an ever-growing list of desired drills quickly emerged as the first challenge of the planning effort. Understanding both the exercise mission and the commander’s intent at each unit became critical enablers to meet both U.S. and Japanese objectives.

Initially, planning for engineering tasks was divided between two working groups to help focus on KEEN SWORD’s primary engineering objectives: airfield damage repair and engineering engagement. The working group leaders, selected from Iwakuni’s facilities department, were permanently assigned engineers with full-time duties related to construction and repair. Each group was tasked with outlining a concept of operations, required resources, and follow-on tasking necessary to achieve objectives.

As the exercise approached, the working groups leveraged years of lessons learned, after-action reports, and pass-down logs to build their plans. Their success at this stage depended heavily on the amount of documentation left behind by the servicemembers who had gone before them. Investing time

in recording successes and failures is crucial for joint force engineers to improve their responsiveness.

Bilateral Knowledge

The roundup of engineers to participate in the exercise combined U.S. Marines and U.S. Navy Seabees, Japanese soldiers and sailors, and civilian employees. The first few days included classroom teaching and hands-on skill-building to level-set terminology, tactics, and techniques. This foundation aligned the many units, which may have been familiar with engineering operations within their organization but were unfamiliar with each other’s methodology.

It quickly became apparent that U.S. servicemembers did things very differently than the Japanese, a good example of how there can be multiple acceptable engineering solutions to the same problem. The challenge for future bilateral events will be to find an optimal solution, tasking units based on their unique strengths, and efficiently using all available resources.

As the exercise approached, the working groups leveraged years of lessons learned, after-action reports, and pass-down logs to build their plans. Their success at this stage depended heavily on the amount of documentation left behind by the servicemembers who had gone before them.

Comparing Skillsets. Each unit delivered a unique capability to the exercise, with some overlap between servicemembers with similar occupations. For instance, Marine Wing Support Squadron 171, based in Iwakuni, provided heavy equipment and operators skilled in airfield paving and aircraft salvage and recovery. Seabees from Naval Mobile Construction Battalion 5, based in Port Hueneme, Calif., shared some of the same heavy equipment and operator skills as the Marines; however, they did not practice aircraft salvage the same way. The two units followed different rigging and lifting protocols, highlighting the laser focus of the Marines on aviation combat support compared to a more general construction focus for the Seabees. Similarly, soldiers with the Japanese Ground Self-Defense Force maintain paving and runway repair skills but they do not use the same type of equipment or materials used by either Marines or Seabees.

To identify these capabilities and limitations, key leaders from each unit participated in a single-day program modeled after the Joint Engineer Operations Course. This helped to define the full scope of tasks expected during crisis and contingency for a combined joint task force engineer. Following the class, leaders formed a workshop to develop a list of capabilities and limitations, an engineer support plan for the scenario, and a gap analysis to help shape future investments.

The engineers also recognized a need to sustain the working relationship being developed during the exercise and committed to meeting throughout the upcoming year, an investment of valuable time and essential to future success as a regional response force.

Hands-On Sharing

The bilateral exercise included several activities intended to share tactics, techniques, and technology across the combined joint engineering forces. Among the most popular events was a demonstration (by MITRE Corp.) of unmanned aerial systems designed to survey an installation. While the unmanned aerial vehicle, survey instruments, and processing systems were not new technology, a system package with all three had not yet been fielded by any of the participating engineering units.

To identify these capabilities and limitations, key leaders from each unit participated in a single-day program modeled after the Joint Engineer Operations Course.

The Geographic Information System Office at Air Station Iwakuni had a similar drone in its inventory but did not have a drone operator. Having the capability to remotely and rapidly survey damaged facilities, without placing servicemembers at risk, while delivering accurate and detailed survey data was immediately recognized by all participants as valuable for future recovery operations. Initial requirements were identified for investments in drone systems, drone operators, and in streamlined processes to approve drone operations.

Roughly a dozen spalls and craters were repaired over the course of 20 working hours. This included the repair of a massive crater that was roughly 11-m in diameter and 36-m³ in volume. Repairs were accomplished using a combination of compacted earth, flowable fill, rapid-set concrete mix, and fiber-reinforced polymer panels. Clearing damaged concrete and twisted reinforcing bars became highly labor-intensive activities.

The engineers used saws, torches, hydraulic hammers, and every available tool to clear debris. They put walk-behind concrete saws, tamping rammers, and portable concrete mixers to the test, and in every phase of site work would become a limiting factor. When equipment failure threatened to slow operations, either through failure or error, the engineers relied on redundancy and repairs. This highlighted a need to maintain a balance between spare equipment, skilled operators, and repair capability.

Runway Repairs. A multi-phase runway repair was the culminating event for the engineers at KEEN SWORD. The scenario included a simulated missile attack on the airfield, resulting in multiple runway spalls and craters, damaged aircraft obstructing runways, and damaged buildings scattered across the base. Response teams were dispatched to survey the damage and report back to an engineering operations center. A minimum operating strip was selected, and repairs were prioritized, scheduled, and then tasked.

Teams were dispatched to clear simulated explosive ordnance, remove damaged aircraft, assemble temporary airfield lighting, start water purification units, and connect portable generators. The ability among participants to communicate quickly, clearly, and securely became the latest challenge and highlighted the importance of preparing and rehearsing a thorough communication plan.

Collaborative Success

Engineering forces must rapidly mobilize and respond to crises—a difficult task under even perfect conditions. Dispersal throughout vast geographic regions, varying capabilities, and different response times all drive military commanders to combine available forces during combined operations. For this reason, the joint force should continue to seek opportunities to prepare engineers to work in combined joint formations.

Both headquarters and program offices should continue emphasizing inter-service training, combined joint exercises, and international student and officer exchanges for the engineering fields. Balancing investments between fielding new technology, maintaining force readiness, and conducting operations is a constant challenge at every level. But it is a cost/benefit analysis made easier by using feedback and lessons directly from the field.

Communicating Effectiveness

An essential element of success during KEEN SWORD was access to technology capable of translating quickly between Japanese and English. Working parties were mixed with engineers from each country to maximize information exchange between allies. However, there were not enough bilingual participants to distribute a translator to every working party. Smartphone translator applications, ChatGPT, and previously translated report templates were used in the field to great success.

Documents like equipment manuals, doctrinal publications, and pre-start checklists were quickly translated either through a camera-based phone application or by uploading them to a ChatGPT website. The few translators on staff were then used to double-check translations and make adjustments, resulting in a dramatic reduction in their workload and streamlining communications between engineers.

Ultimately, the team realized that translators with security clearances, classified and unclassified AI tools, and mobile camera-based translator applications are key engineering resources needed on the job site. They deserve to be added to standard operating procedures and preparatory checklists.

Cdr. Edward Fosson, P.E., M.SAME, CEC, USN, is Facilities Officer, Marine Corps Air Station Iwakuni, Japan; efosson@gmail.com.

Published in the March-April 2025 issue of The Military Engineer

Check Out Related Articles From TME

-

Deploying Renewable Generation Through Small-Scale Hydropower

A field demonstration and ongoing investigation of modular hydrokinetic turbines by the U.S. Army Engineer Research & Development Center’s Construction Engineering Research Laboratory illustrates the potential applicability for using the technology on military deployments. -

Rethinking Traditional Treatment Systems for PFAS Remediation

At two U.S. Air Force bases impacted by historical releases of aqueous film-forming foam, innovative methods in treating PFAS in both surface water and groundwater provide examples of success in safeguarding health for military personnel and nearby communities. -

Tackling Restoration Projects With Amphibious Excavators

When faced with soft and wet underfoot conditions, such as at a recent channel dewatering, excavation, and repair project for USACE Galveston District, amphibious excavators offer a scalable way to contour difficult site characteristics. -

Big Job, Small Solutions: Completing a Complex Remediation in Remote Alaska

At a remote federal remediation site in south-central Alaska, inaccessible by road, barge, or large planes, leveraging the local community and a fleet of snowmobiles and small watercraft allowed for 1,100 bags of contaminated soil to be transported for offsite disposal. -

Regenesis Offers Full-Spectrum PFAS Remediation

For project stakeholders and remediation managers confronted with PFAS, Regenesis demonstrates why in situ treatment using Regenesis’ PlumeStop® colloidal activated carbon (CAC) is a game changer. -

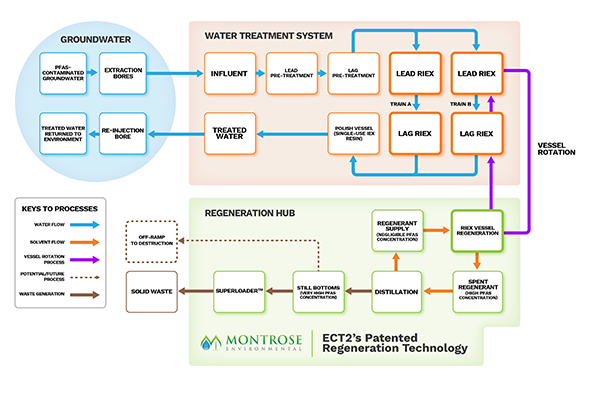

100 Percent PFAS Compliance with Regenerable Ion Exchange Resin

The operational success of a RIEX system spotlights its successful approach to combating PFAS in an effective and economical manner. (Sponsored Content)