Tackling Restoration Projects With Amphibious Excavators

By Matt Smith, M.SAME, and Angelica Fonseca, M.SAME

When faced with soft and wet underfoot conditions, such as at a recent channel dewatering, excavation, and repair project for USACE Galveston District, amphibious excavators offer a scalable way to contour difficult site characteristics.

Through their unique capabilities, amphibious excavators can be highly effective when utilized on environmental projects. These specialized machines are able to effectively remove sediment build-up, reshape shorelines, and stabilize eroding banks while minimizing damage to sensitive ecosystems thanks to their low ground pressure design. This versatility is further enhanced by how they can be specialized with attachments such as dredging pumps, vegetation cutters, and grapples.

Amphibious excavators can play a crucial role in promoting environmental sustainability and improving the efficacy of restoration efforts across diverse aquatic landscapes. These machines have transformed operations in many highly challenging environmental sites, particularly locations traditionally considered difficult to navigate.

A recent example of their benefits is a dewatering and dike repair carried out for the Galveston District of the U.S. Army Corps of Engineers (USACE). The scope of work presented enormous challenges, primarily due to the soft and wet underfoot conditions. As a result of the advancements in amphibious machinery, the onsite team was able to tackle these issues more effectively, while managing the complexities of the demanding environments.

Sensitive Terrain

An amphibious excavator is specifically designed to maneuver in soft underfoot conditions, while featuring the ability to float on water as an added safety feature. This type of excavator is completely self-propelled, which grants it the ability to access virtually any soft terrain where standard excavators cannot operate. The machines play a very useful role in environmental work, leveraging dual functionality to float on water while also working on land.

This capability allows an amphibious excavator to access sensitive wetlands with minimal disruption to the ecosystem. By combining versatility with an emphasis on protecting fragile habitats, the amphibious excavator proves to be invaluable for a wide range of applications in areas often considered inaccessible.

Regional Importance

The scope of work for the Galveston District project stemmed from the pressing need to widen and deepen the Houston ship channel, which was driven by the economic volume conducted through this critical shipping lane, as well as the growing concerns regarding navigational safety and the potential risk of vessel collisions.

Essential dredging-related tasks were performed for the site, which is identified as Placement Area 14, including clearing and grubbing, perimeter trenching, lateral trenching, the removal and drying of dredging spoils, and the construction of a semi-compacted dike utilizing stabilized soil.

Dual-Purpose Design

The amphibious excavator is a combination of a standard excavator upper structure and a specialized undercarriage (pontoons), which decrease the machine’s ground pressure to less than 2.5-psi. Some models of pontoons will allow the excavator to float in water deeper than 5-ft. The pontoons also can be outfitted with a supplementary side pontoon system that increases the buoyancy and allows the excavator to perform work while floating by deploying the piles into the ground below.

In many cases, the amphibious excavator is configured with a longer reach boom and stick combination that will provide up to 50 percent more reach. The pontoons will have any number of additional drive motors that help to propel the significantly larger track systems.

After initial dredging was completed, the spoils were pumped several thousand feet to the designated placement area. The contractor then began to excavate the 16 lateral trenches with a combined 34,000-ft and another 13,000-ft of perimeter trenches.

The complexity of this operation was increased because the positive drainage had to be maintained throughout, but there was very little elevation change to work with. As a result, the amphibious excavators had to be outfitted with GPS machine control to ensure the proper drainage specification was attained.

The excavation also necessitated that the dredging spoils to be a minimum of 150-ft from the centerline of the trench. However, the water content of the material was such that it would recede back to the trench. This required the material to be relayed to another excavator with a 60-ft long reach, which then placed it past the 150-ft requirement.

Due to the exceptionally soft dredging material present, standard excavators would have been ineffective. The specialized equipment used, with its multi-drive system, played a crucial role in overcoming site constraints.

In total, nine amphibious excavators were used to complete the shipping channel project, averaging 120-ft of excavation per day, per team of three excavators.

Expediting Timelines

For a delicate project to rehabilitate a pair of exposed pipelines on the Quinnipiac River in Connecticut and ensure the continued delivery of safe and reliable energy for the region, amphibious excavators were key to successfully and safely completing the work and maintaining environmental stewardship throughout.

The contractor (Charps LLC) used an amphibious excavator from inside the river to dig around the exposed pipeline, repair it, and then install 430-yd³ of riprap, measuring from 15-in to 30-in, along with 500 sandbags around the pipeline to protect it in the future.

The dredging was scheduled to take at least two months, if not more. Using an amphibious excavator allowed access to the pipeline from the river, which enabled the job to be completed in half the time. This was all done while the team assured that the project met safety specifications and caused no additional harm to the surrounding environment. That included using eco-friendly hydraulic oil to protect local habitats in case of any leaks.

The shipping channel dredging success underscores the infrastructure developments necessary for enhancing navigational safety and the corollary benefits to the economy.

Expanding Capabilities

Amphibious excavators bring a variety of benefits to the environmental construction and engineering community. They can provide the necessary reduction in ground pressure to keep workers on top of the material, causing minimal damage to the environment around it. When configured with a long reach excavator, these machines can reach either deep under the water, or from the bank to clean out the sediment below.

Amphibious excavators are expanding the capabilities of project teams. Augmenting the typical environmental jobsite with this type of machine can create a powerful advantage for the contractor and project owner in time savings as well as technical capabilities and work capacity.

Matt Smith, M.SAME, is Vice President and Angelica Fonseca, M.SAME, is Director of Market Development, EIK Solutions.

They can be reached at matt@eiksolutions.com; and angelica@eiksolutions.com.

Published in the January-February 2025 issue of The Military Engineer

Check Out Related Articles From TME

-

Deploying Renewable Generation Through Small-Scale Hydropower

A field demonstration and ongoing investigation of modular hydrokinetic turbines by the U.S. Army Engineer Research & Development Center’s Construction Engineering Research Laboratory illustrates the potential applicability for using the technology on military deployments. -

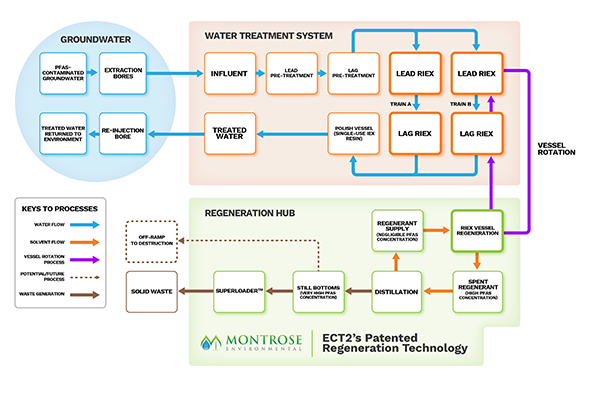

Rethinking Traditional Treatment Systems for PFAS Remediation

At two U.S. Air Force bases impacted by historical releases of aqueous film-forming foam, innovative methods in treating PFAS in both surface water and groundwater provide examples of success in safeguarding health for military personnel and nearby communities. -

Tackling Restoration Projects With Amphibious Excavators

When faced with soft and wet underfoot conditions, such as at a recent channel dewatering, excavation, and repair project for USACE Galveston District, amphibious excavators offer a scalable way to contour difficult site characteristics. -

Big Job, Small Solutions: Completing a Complex Remediation in Remote Alaska

At a remote federal remediation site in south-central Alaska, inaccessible by road, barge, or large planes, leveraging the local community and a fleet of snowmobiles and small watercraft allowed for 1,100 bags of contaminated soil to be transported for offsite disposal. -

Regenesis Offers Full-Spectrum PFAS Remediation

For project stakeholders and remediation managers confronted with PFAS, Regenesis demonstrates why in situ treatment using Regenesis’ PlumeStop® colloidal activated carbon (CAC) is a game changer. -

100 Percent PFAS Compliance with Regenerable Ion Exchange Resin

The operational success of a RIEX system spotlights its successful approach to combating PFAS in an effective and economical manner. (Sponsored Content)